Your Future Supplier of Recycled-Origin Mineral Fillers and Industrial Minerals

About Us

Trisector is implementing an innovative plant to upcycle coarse mine tailings into the growing need for sustainable secondary mineral raw materials, such as industrial minerals for construction, road building and agroforestry applications and functional fillers used in plastics, paper, paints and sealants.

Our Mission

Trisector is committed to apply resource-efficient solutions for producing upcycled mineral materials, helping industries reduce their reliance on newly extracted raw materials, that can adversely affect the environment.

The increased focus on ‘sustainability’ values, encompassing metrics like specific energy consumption, specific water consumption and carbon footprint highlights a shift where traditionally sourced mineral materials may be replaced by sustainable alternatives.

Resource Efficiency

Trisector's recycled mineral materials offer a crucial solution for manufacturers and builders to meet the growing demand for resource efficiency, using recycled materials, driven by legislation and consumer behaviour.

Trisector understands how climate concerns have elevated sustainability commitments as the new norm and guiding principle for our economic development and the priorities to re-use materials and reduce waste.

The legislators around the world use enforcement mechanisms involving legislation, regulations, and standards that set mandatory targets, requirements, and incentives for product manufacturers to reduce resource consumption, minimize waste generation, and promote recycling and reuse.

Consumers are becoming more conscious of the environmental impact of their consumption choices and are seeking options that minimize waste, promote recycling, and contribute to a circular economy. This shift in consumer behavior is influencing businesses to adopt more sustainable practices throughout their value chains.

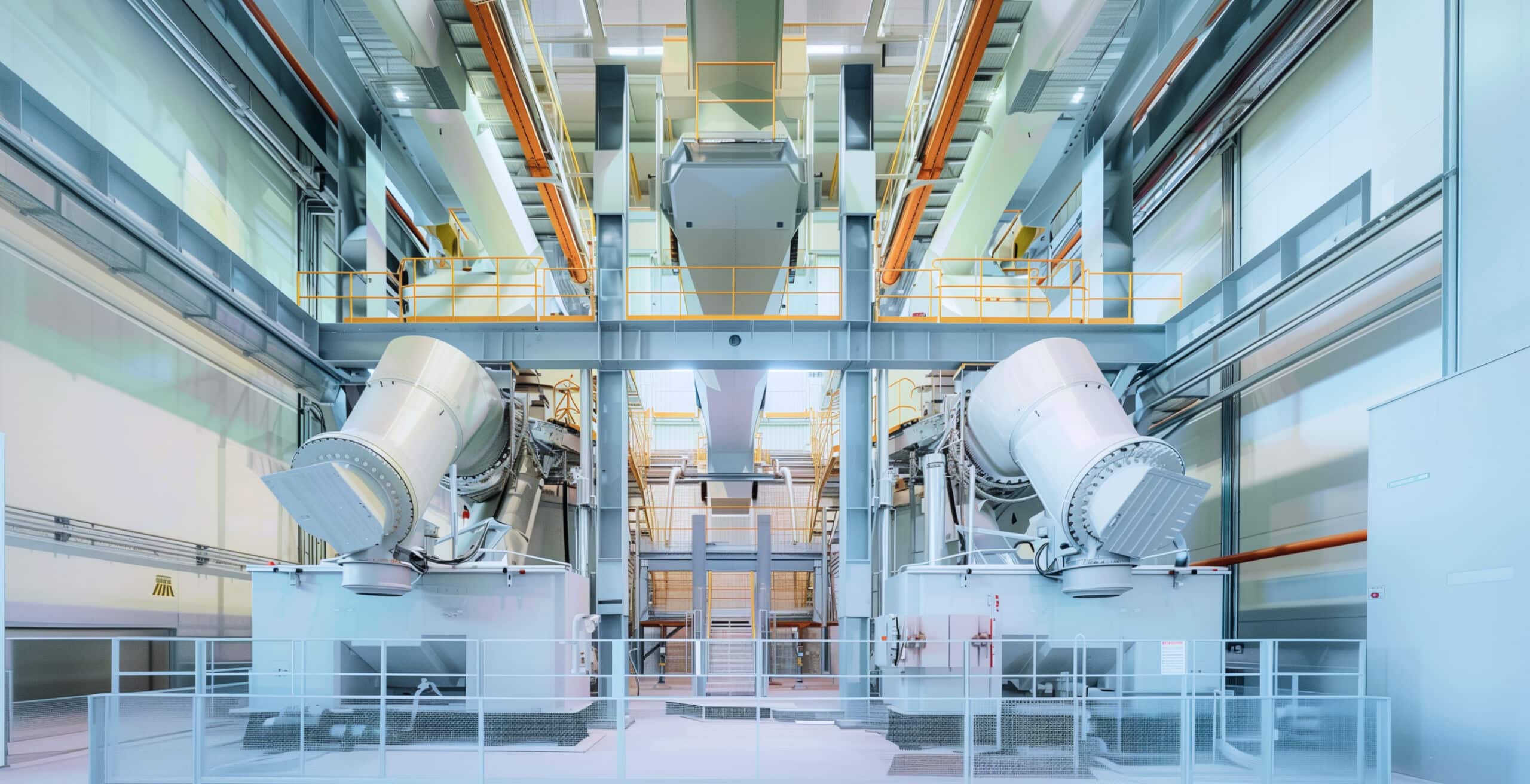

Process & Digitalization

Producing customized secondary mineral raw materials with a consistent output and rigorous quality assurance.

The upcycling process uses our unique technology to go beyond what’s expected for sustainable production. We use advanced technologies, including industrial-edge production, to make better use of resources like electricity and water. The highest technological standards in plant design and operations helps us improve resource efficiency and performance in producing consistent quality products.

We make sure to maximize using renewable energy in our process. Our goal for the production of upcycled mineral products is to reduce CO2 emissions by 80%, cut water use by 50%, and lower energy use by 30% compared to the production of similar products available on the market.

Our Goal

We prioritize maximizing the use of renewable energy in our process.

Our goal for the production of upcycled mineral products is to reduce CO2 emissions by 80%, cut water use by 50%, and lower energy use by 30% compared to the production of similar products available on the market.

Our baseline objective for the upcycled products is to achieve, compared to the production of similar products on the market

80%reduction in CO2 emissions

50%decrease in water consumption

30%cut in energy consumption

Ecosystem

Resource Efficient Value Innovation.

Data driven ecosystem

From Waste to Carbon Neutral Raw Materials. Integrated supply change.

0

Mineral Waste Rock

More than 100 million tons of of leftover materials from mining

1

Zero Waste Technology

We aim to upcycle 100% of leftover materials into secondary raw materials

2

Clean Energy

Our goal is to maximize the use of renewable energy.

3

Upcycled Raw Materials

- Calcium Carbonate

- Industrial Minerals

- Kerogen Concentrate

4

Value Added Raw Material Applications

Value-adding industries are the cornerstone of an economy, locally transforming secondary raw materials into high-quality products that fuel innovation and economic growth.

5

Carbon Free Logistics

Carbon-free logistics are essential for limiting the Scope3 label of our products, reducing the environmental impact and supporting resource efficiency in the supply chain

Cooperation & Regional Benefits

The creation of a new industry is a driving force positively transforming the regional economic dynamics.

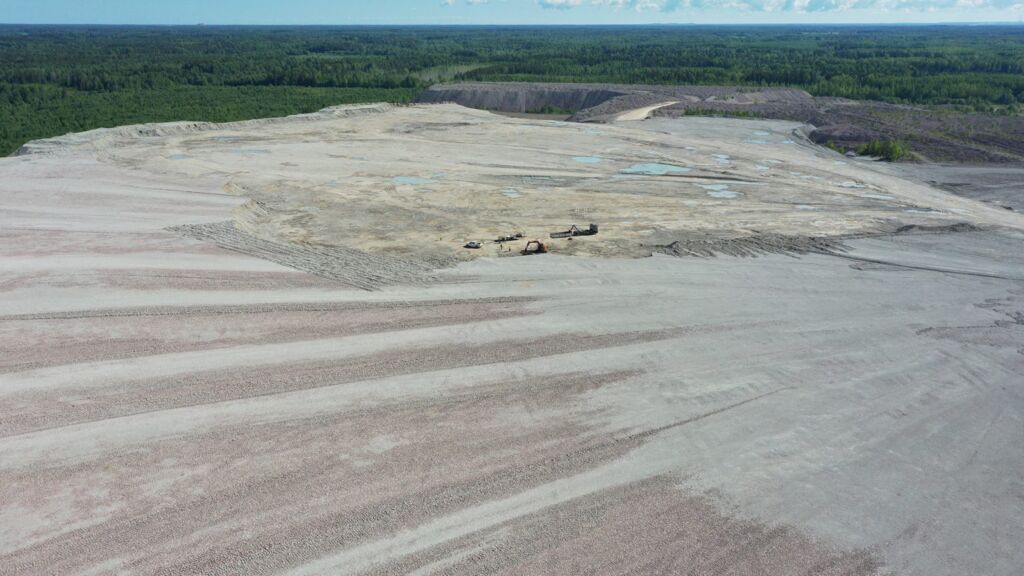

In partnership with Enefit Industry, Trisector has the potential to access more than a 100 million tons of leftover materials from mining, collected over 50 years. The collaboration aims to tackle the large amount of mine tailings produced and deposited from the beneficiation of a coarse size oil shale run-of-mine, at Estonia Mine. The upcycling of the leftovers to secondary raw materials aligns with Enefit Industry’s goals to use resources more efficiently, reduce waste and promote circularity.

The goal is to process over 1 million tons of the leftover materials each year at the Estonia Mine.

The effort by Trisector helps deal with the significant mining residue issue in Ida-Virumaa and supports the global Sustainable Development Goals and the Nature Restoration objectives.

Core Team

At present, our core team consists of four professionals with diverse business backgrounds.

We are currently collaborating with almost a hundred researchers and specialists to realize our vision.

Mikko Hedman

CDO & Sales

Paavo Pettai

Head of Marketing & Communication

Aleksandr Snatkin

CFO

Arnout Lugtmeijer

CEO

News

Stay up to date with our latest news

Connect and Collaborate for a Resource-efficient Future!

"*" indicates required fields